As I mentioned before we were a large family. When the war broke out, I was just 12 years old and there were 12 children already in our family. I believe the marriage was good, and as children we could get along quite well, apart from some minor rivalry that typically happens among children. Looking back, I had a happy youth. Dad and Mom were busy and worked long days but were seldom away from home and as we often had to help, and the small ones were kept nearby as they worked so we spent plenty of time with them. The days were well filled with chores so we didn’t have much time for mischief.

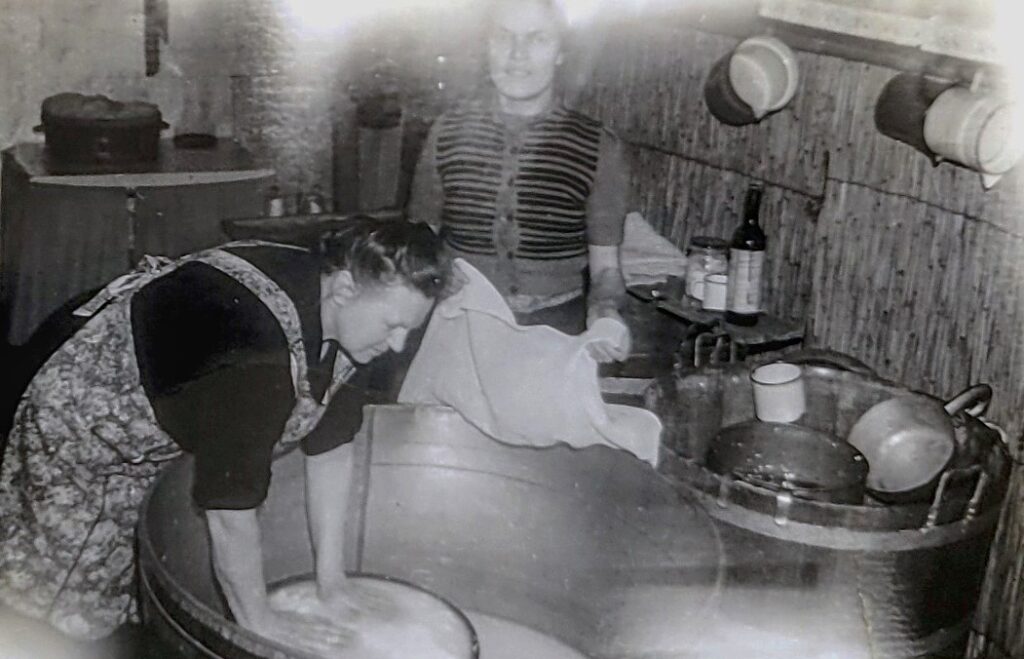

In summertime, the day started at 3:30 or 4:00 am for my parents when they started milking. We usually had between 20 and 25 milk cows. Milking was usually done with 3 or 4 of them and everything was done by hand. They came back with the milk around 6:00. The milk was then poured into a big wooden form (kaas tobbe). The temperature was checked as this was very important for cheese making and had to be exactly right. Through experience we knew while milking when the milk cans had to be covered to maintain the right temperature. If they needed to be cooled this was done by putting a number of cans inside the boat to sit in the water and with hot or cold water we brought the milk to the exact temperature. If it was not quite right a few additives were added, precisely measured according to the amount of milk. The number of milk cans indicated how much milk there was. The most important additive was rennet. Then we covered the cans and went for breakfast as cheesemaking started half an hour after the rennet was added.

After breakfast cheesemaking started. The rennet had changed the milk into a gel like product, almost like pudding. Then we started to cut it, at first very slow and course and then a little faster. This took 15 minutes, then we let it stand for another 15 minutes and then removed part of the whey that had formed and with hot water brought the temperature several degrees higher and stirred for about 10 minutes, then another rest, whey removed, etc. Soon the cheese was ready to be put in the form. We had all sizes of forms and the right form had to be used according to the amount of milk otherwise the cheese would be too flat or too high. After a while the cheese was turned and put under the press, and after a while turned again and more pressure added. When the cheese was half a day old it was put into a weak brine and had to be turned a few times a day, then after 1 or 1 ½ days it was put into a stronger brine for a few days. The bigger the cheese, the longer it sat in the brine. While making cheese there were moments when you could rest for a few minutes, but there were also many other jobs to be done.

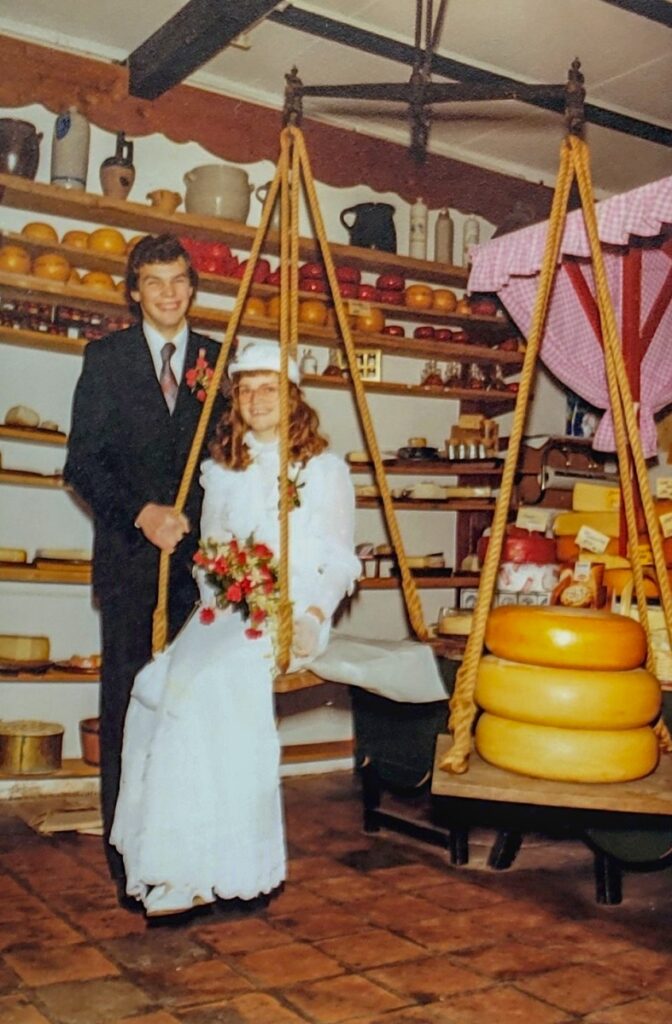

We made cheese from about 40 lbs a piece in the summer to about 15 or 20 pounds in the fall. Sometimes in winter we made cheese only once a day and sometimes we stopped for a while when the amount of milk was too low and we shipped what milk we had to the factory instead. By 8:00 or 9:00 in the morning all the chores around the barns were finished and then field work started. We had a hot meal at noon and after that a short afternoon nap followed by field work and then another round of milking and cheese making started again at 3:30 in the afternoon.

After supper the pigs and calves had to be fed and other small jobs but only when it was very busy was fieldwork also done after supper. Gardening was not considered field work so this was mainly done in the evening.

Cheese Making

Leave a Reply